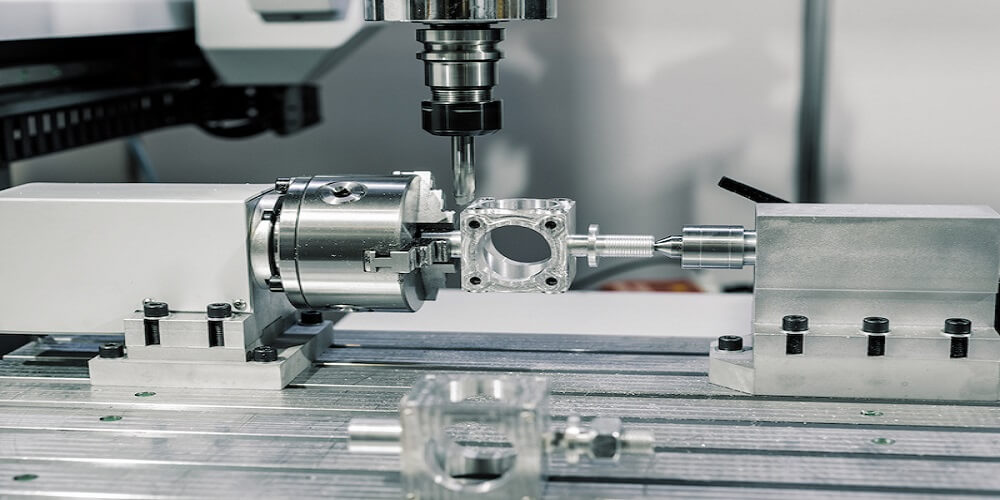

Since the introduction of milling in the technical world, milled parts are now commonly used in different industries. A milling machine can be utilized in the machining of parts such as plastics, wood, and metals.

Different types of machining processes require different types of machines. This is to say that not all types of milling machines are suitable for every kind of raw material.

The two basic types of milling centers are horizontal and vertical milling. Both of them are different in their abilities due to their structural differences.

Most machines are either vertically or horizontally oriented. However, most companies use both horizontal and vertical milling machines to satisfy every need of customers.

Vertical Milling Machine

As implied by the name, a vertical milling machine is built with a vertical spindle axis. The two types of vertical mills include the bed mill and the turret mill.

In a bed mill, the raw material used is kept on a bed that rocks to and fro horizontally. While the turret includes a bed that moves both ways -vertically and horizontally with a fixed spindle.

Vertical milling is particularly suitable for plunge cuts and drilling because of the way they are structured.

Below are the benefits of Vertical milling

· Visibility

Here, orientation is quite open and therefore very visible to the operators. When faced with projects that require details, vertical milling comes in handy. However such projects cannot be rushed

· Cost

Vertical milling machines are more affordable than horizontal milling machines. They are readily available in the market because people prefer to use them more than horizontal machines.

· Precision

Cuts made by vertical milling machines are accurate and consistent. The use of this machine ensures a great reduction in human error usually seen in manual machines.

· Ease

Even for people who are new in the field, operating a vertical milling machine isn’t such a difficult task. It is user-friendly and quite easy to maneuver.

Because this type of milling is popular, finding skilled labor for your project will be easy as well. Unlike horizontal milling, vertical milling doesn’t demand special fixtures or expertise.

Horizontal Milling Machine

In a horizontal milling machine, the cutting tool resembles that of a circular saw. They consist of numerous customizations including rotating universal beds and multiple cutters.

This setup enables you to cut on any angle you desire and not just horizontally. Using a horizontal mill is similar to cutting with different tools at the same time.

Below are the benefits of Horizontal Milling

· Speed

Horizontal machines cut at a very fast rate. Some machines are even capable of cutting different pieces simultaneously still at a very high speed. Removing chips is also easy and is done faster.

· Durability

This machine is built with high-quality sturdy materials and therefore they don’t spoil easily. Because they are very strong, they are not at risk of damage even if the raw materials they are meant to work on are heavy.

· Capacity

If you wish to work on a large or a lengthy piece, the horizontal milling machine is your best bet. Because the process is fast and precise, it can effortlessly work a large piece of raw material.

Conclusion

As explained above, both milling machines have their distinct advantages. While both of them are important, care should be taken when choosing one if you cannot afford both.