Custom machined parts are in most items we depend on and use every day. These parts come in a wide variety from simple to intricate designs. China is the leading producer of the best-machined parts in the world. Companies manufacture the parts from high-quality products, after which they are sold at a reasonable price.

Depending on where one wants to use the parts, there’s a wide range of product options. The availability of engineers and designers ensure that your design requirement is met. Engineers head the production team to ensure you get the best quality machine parts. When starting a project that needs machined parts, put in mind, there are two types; customized and standard machine parts.

1. Standard machined parts

For standard machine parts, components are available in the market, making it the best solution. It is cheap since no redesigning gets involved.

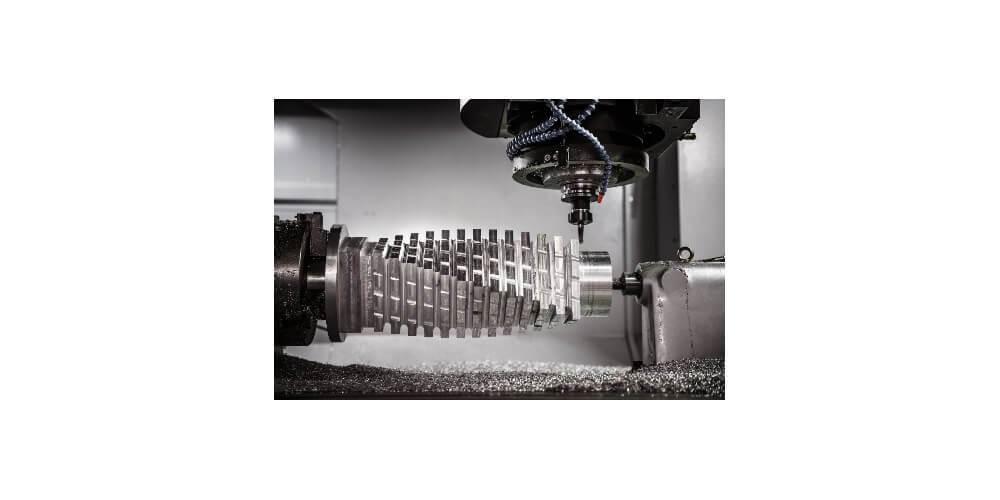

2. Customized machined parts

Customized machine parts refer to parts that aren’t in the market; an engineer has to redesign them to meet a client’s requirement. The process is known as customization. The process takes longer since they have to be reproduced, leading to extra charges. The good thing is that you can add features to your machine parts to meet the requirements.

Components of Custom Machined Parts

Customized machined parts use plastic and metal materials in the market. Below is a list of the elements;

· ABS

· Carbon Fibre

· Copper

· Brass

· Titanium

· Aluminum

· Rubber

· Peek

· Bronze

· Polycarbonate

· Stainless steel

· Delrin

Ways in Which Parts Get customized

· Self-development- In this case, a person has an idea of the part that needs to be customized. They draw it and then take it to the manufacturer.

· Collaborative development- In this case, one has no idea on the custom-design, designers help the person with information to help them choose the best design for their machined parts.

· Adaptive customization- This method favors manufacturers. On the client’s side, there are several restrictions. The base parts can be adjusted according to the needs of the customer.

The manufacturer can produce large amounts of pieces that can be customized without interfering with the whole process.

· Cosmetic customization- This method involves the creation of different styles, such as color for one product. Cosmetic customization is the best method for high-volume production.

Benefits of Customized Machined Parts

· The time that would be used looking for parts no longer in the market is saved.

· When CNC machines are used, it’s easy to get identical parts since designs are stored on a computer.

· Parts with no use get customized and become useful to the owners. They can, for example, be customized and used in other machines.

Final Thoughts

It’s easy to understand designs used in parts since they are a part of our lives. To manufacture custom components, one needs to use technology and trained professionals. From the introduction of automated and computerized equipment, production time has reduced. Large numbers of unique parts get produced since it’s cheap to manufacture custom machined parts. Some materials such as bronze need the use of CNC machines, for someone with a project that requires custom machined parts, it’s best to choose a manufacturer that uses specialized equipment. Click here and get your machined part projects started today.